Silicon bronze welding requires specialized knowledge and wire selection based on unique material properties like corrosion resistance and strength. Wire choices include solid core for thin materials, flux-core for thicker materials, and BMT wires for structural repairs. Optimal selection balances application needs, environmental factors, and silicon bronze's characteristics, focusing on melting point, tensile strength, and conductivity while emphasizing sustainability in marine, automotive, and tire services.

“Unleash the potential of silicon bronze welding with our comprehensive guide. Effective welding requires an understanding of the unique properties and demands of this alloy. This article explores the core considerations for successful silicon bronze welding, focusing on the ideal wire types. We’ll navigate through various options, each offering distinct advantages, to help you choose the best fit. Additionally, discover the subtle factors that can sway your decision, ensuring optimal results in every weld.”

- Understanding Silicon Bronze Welding Requirements

- Types of Wire for Efficient Welding Process

- Factors Influencing the Best Wire Choice

Understanding Silicon Bronze Welding Requirements

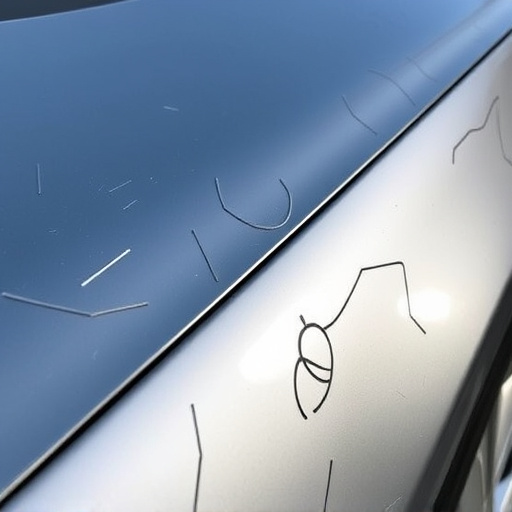

Silicon bronze welding is a specialized process that requires understanding the unique properties and demands of silicon bronze as a material. This alloy, known for its excellent corrosion resistance and strength, poses specific challenges during welding due to its high silicon content. The key to successful silicon bronze welding lies in selecting the right wire, which should match the material’s characteristics to ensure robust and durable connections.

When considering wires for this process, several factors come into play. The choice of wire diameter must be precise to accommodate the joint requirements without compromising strength or aesthetics. Additionally, the wire’s coating is critical; it should facilitate smooth fusion while preventing contamination from oxidation or other environmental factors, which are common in automotive restoration and auto repair near me settings, including Mercedes Benz collision repair shops.

Types of Wire for Efficient Welding Process

When it comes to silicon bronze welding, choosing the right wire is paramount for achieving a successful and efficient welding process. The primary types of wire used in this technique include solid core, flux-core, and bare metal transfer (BMT) wires. Each option offers unique advantages tailored to different welding scenarios. For instance, solid core wires are ideal for thin materials as they provide precise control during the welding process. These wires also require a separate shielding gas, ensuring a cleaner weld bead but demanding more setup time.

In contrast, flux-core wires streamline the process by incorporating a built-in flux that cleans and prepares the joint area as the wire melts. This makes them suitable for thicker materials and faster welding in collision centers or car repair shops. Bare metal transfer (BMT) wires, on the other hand, are designed to deposit minimal filler material, making them perfect for high-quality, structural welds in applications like vehicle body repair. Their efficiency is particularly notable in reducing heat input, minimizing distortion, and ensuring robust bonds, all of which are crucial aspects in collision center operations.

Factors Influencing the Best Wire Choice

The choice of wire for silicon bronze welding is influenced by several key factors. First and foremost, the specific application plays a pivotal role in determining the best wire type. For instance, while silicon bronze excels in resistance to corrosion and thermal expansion, making it ideal for applications like marine and automotive components (including vehicle dent repair and frame straightening), the wire used should complement these properties. The melting point, tensile strength, and conductivity of the wire must align with the demands of the welding process.

Additionally, environmental considerations come into play, especially in industries where sustainability is paramount. The wire’s composition and ability to withstand exposure to various elements without compromising structural integrity are crucial. This is particularly relevant in tire services, where silicon bronze components often require regular replacement due to harsh conditions. Ultimately, selecting the right wire for silicon bronze welding involves a careful balance of material properties, application-specific needs, and environmental factors.

In conclusion, choosing the right wire is paramount for successful silicon bronze welding. Understanding the unique requirements of this process and considering factors like wire composition, diameter, and flux compatibility ensures optimal results. Among various options, solid core wires with specific alloys prove most effective, offering enhanced joint strength and corrosion resistance. By carefully selecting the best wire type based on these criteria, welders can achieve high-quality, durable silicon bronze welds, meeting the demands of diverse industrial applications.