Silicon bronze welding, a specialized process for automotive metalwork, requires selecting suitable wire to match its unique properties. Copper-based wires are popular due to conductivity and corrosion resistance, with specialized choices for collision repair enhancing mechanical strength. Wire selection must consider metal compatibility, application needs, composition, diameter, and coating, especially for outdoor use. The welding method influences wire choice, with precision work favoring thin, flexible wires and industrial applications demanding thicker, heat-resistant options.

“Discover the secrets to achieving robust and reliable silicon bronze welding with the right wire selection. This comprehensive guide delves into the unique requirements of this specialized process, offering insights on choosing between various wire types. From understanding the metal’s properties to considering wire composition, we explore factors crucial for optimal results. By the end, you’ll be equipped to make informed decisions, ensuring top-quality welds in silicon bronze applications.”

- Understanding Silicon Bronze Welding Requirements

- Types of Wire for Consideration

- Factors Determining Optimal Wire Choice

Understanding Silicon Bronze Welding Requirements

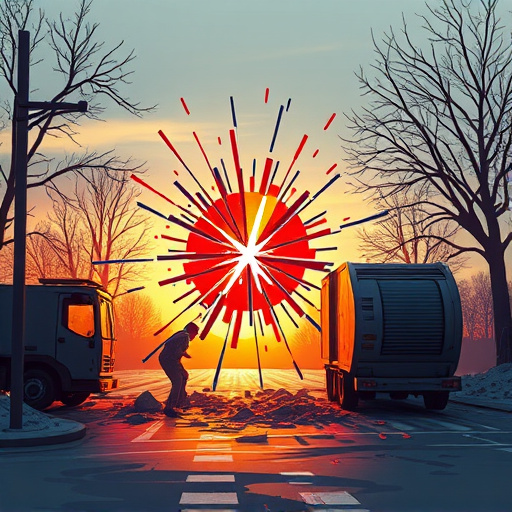

Silicon bronze welding, a specialized technique, requires a deep understanding of its unique demands. This type of welding involves joining metal components, often used in automotive parts, specifically in collision repair centers and fender benders. The process demands specific considerations due to silicon bronze’s distinct properties; it is known for its excellent corrosion resistance and strength, making it a preferred choice for durable welds.

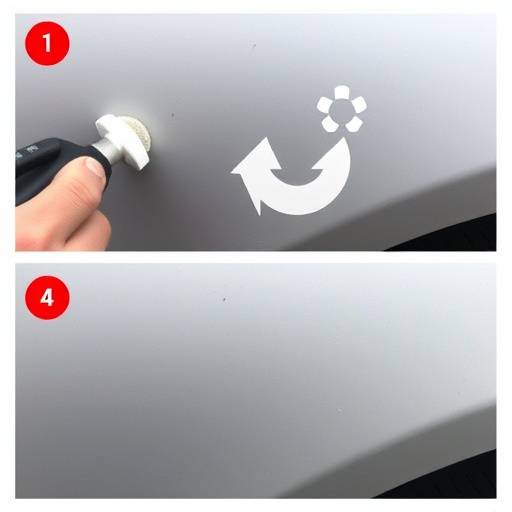

To achieve successful silicon bronze welding, the right wire selection is crucial. The wire should complement the metal’s characteristics, ensuring a strong bond. In vehicle collision repair scenarios, where precision and structural integrity are paramount, choosing the appropriate wire for this specific welding process can significantly impact the final product’s quality and longevity, especially in high-stress areas like fenders and frames.

Types of Wire for Consideration

When it comes to silicon bronze welding, choosing the right wire is key for achieving strong and lasting bonds. The market offers several types of wires suitable for this specific welding process, each with unique characteristics tailored to different applications. For instance, copper-based wires, such as those made from high-purity copper or its alloys like silicon bronze, are popular choices due to their excellent conductivity and resistance to corrosion, making them ideal for both artistic metalwork and structural applications in vehicle bodywork and car restoration projects.

In the realm of collision repair, where precision and durability are paramount, specific types of wires designed with enhanced mechanical properties and improved flow characteristics come into play. These wires often incorporate elements like nickel or zinc to boost their strength and resistance to heat-related deformation, ensuring reliable welds even in challenging conditions. The right wire selection can significantly impact the success of any silicon bronze welding project, whether it’s for intricate artistic designs or structural repairs in car restoration or collision repair work.

Factors Determining Optimal Wire Choice

When selecting wire for silicon bronze welding, several factors come into play. The primary consideration is the compatibility with the specific type of metal and the intended application. Silicon bronze, a unique alloy known for its corrosion resistance and strength, requires a wire that can match its properties to ensure strong and reliable welds. The wire’s composition, diameter, and coating are all critical aspects. For instance, a wire with an appropriate zinc or aluminium coating can enhance corrosion protection, making it ideal for outdoor vehicle repair services where auto glass replacement might be necessary.

Furthermore, the welding process itself dictates wire choice. Different techniques like flux-core or gas metal arc welding (GMAW) have varying requirements. In body shop services where precision and aesthetics are key, a thin, flexible wire with fine coatings may be preferred. Conversely, heavy-duty applications could demand a thicker wire capable of handling high heat and stress, similar to what you’d find in industrial settings beyond vehicle repair services.

In conclusion, choosing the right wire for silicon bronze welding involves understanding the unique requirements of this alloy and considering various types of wires. By evaluating factors such as composition, diameter, and melting point, welders can opt for the best-performing wire, ensuring superior joint strength and durability in this specialized welding process. Silicon bronze welding, when done right, opens doors to robust applications across diverse industries.